Exploring Half-Cut Solar Modules: A Comprehensive Overview

In the ever-evolving landscape of solar technology, half-cut solar modules stand out as a beacon of innovation, promising to propel the industry into new heights of efficiency and productivity. But what exactly are these pioneering devices, and why are they causing such a buzz among solar panel manufacturers ? This blog will shed light on the intricate workings, benefits, and potential drawbacks of mono half-cut and mono PERC half-cut panels, offering a thorough exploration of why they might just be the future of solar energy. By the end, you'll not only be well-versed in the intricacies of these solar PV modules but also be able to gauge their impact on the broader quest for sustainable energy solutions.

What is Half cut solar cell?

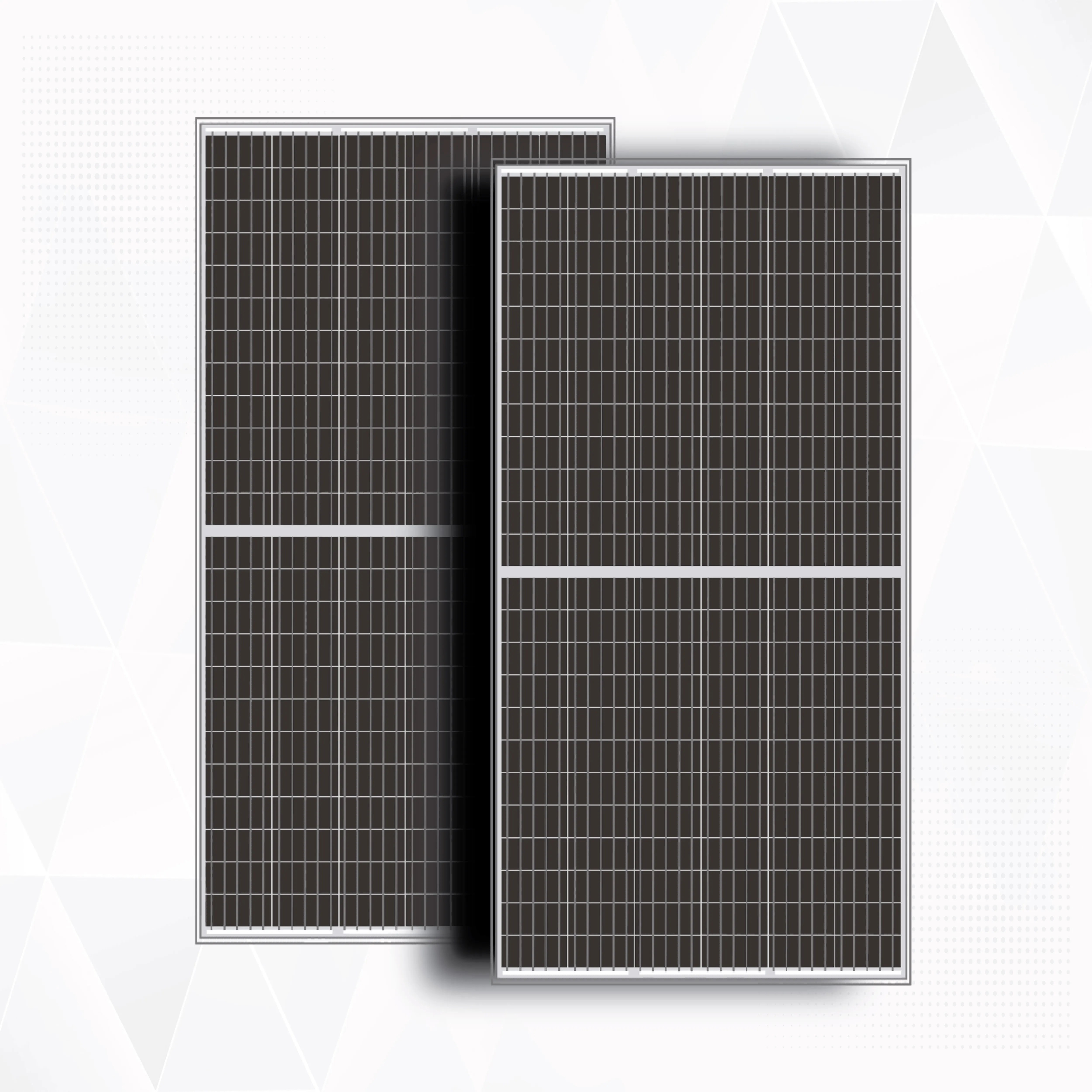

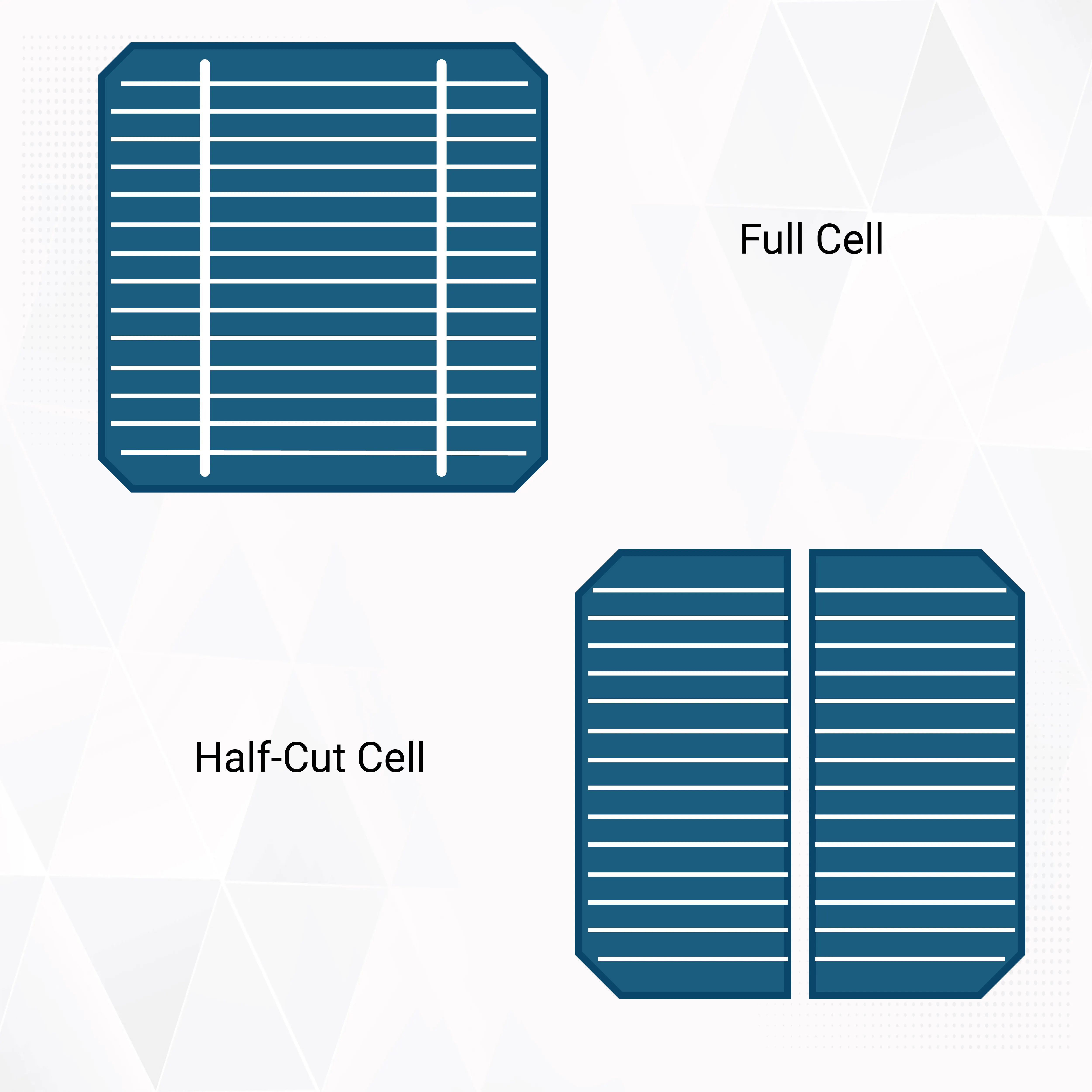

Half-cut solar cells are designed as rectangular silicon units, each possessing roughly half the surface area of conventional square solar cells. These are then interconnected to form a solar module. The primary benefit of adopting half-cut solar cells lies in their reduced energy dissipation due to resistance and heat, enabling an overall enhancement in the solar panel's efficiency.

Furthermore, half-cut cells offer a unique wiring configuration, dividing the solar panel into two distinct sections. This setup ensures that one section can continue operating at optimum efficiency, even if the other section becomes obscured by shade.

How do half-cut solar cells work?

Half-cut solar cell technology enhances the energy output of solar panels by reducing the size of the cells, which allows for a greater number of cells to be incorporated into a single panel. This innovative approach involves splitting the panel into two separate sections, enabling the upper and lower halves to operate independently. As a result, energy production is sustained even if one section is under shade. Let's delve deeper into the specifics.

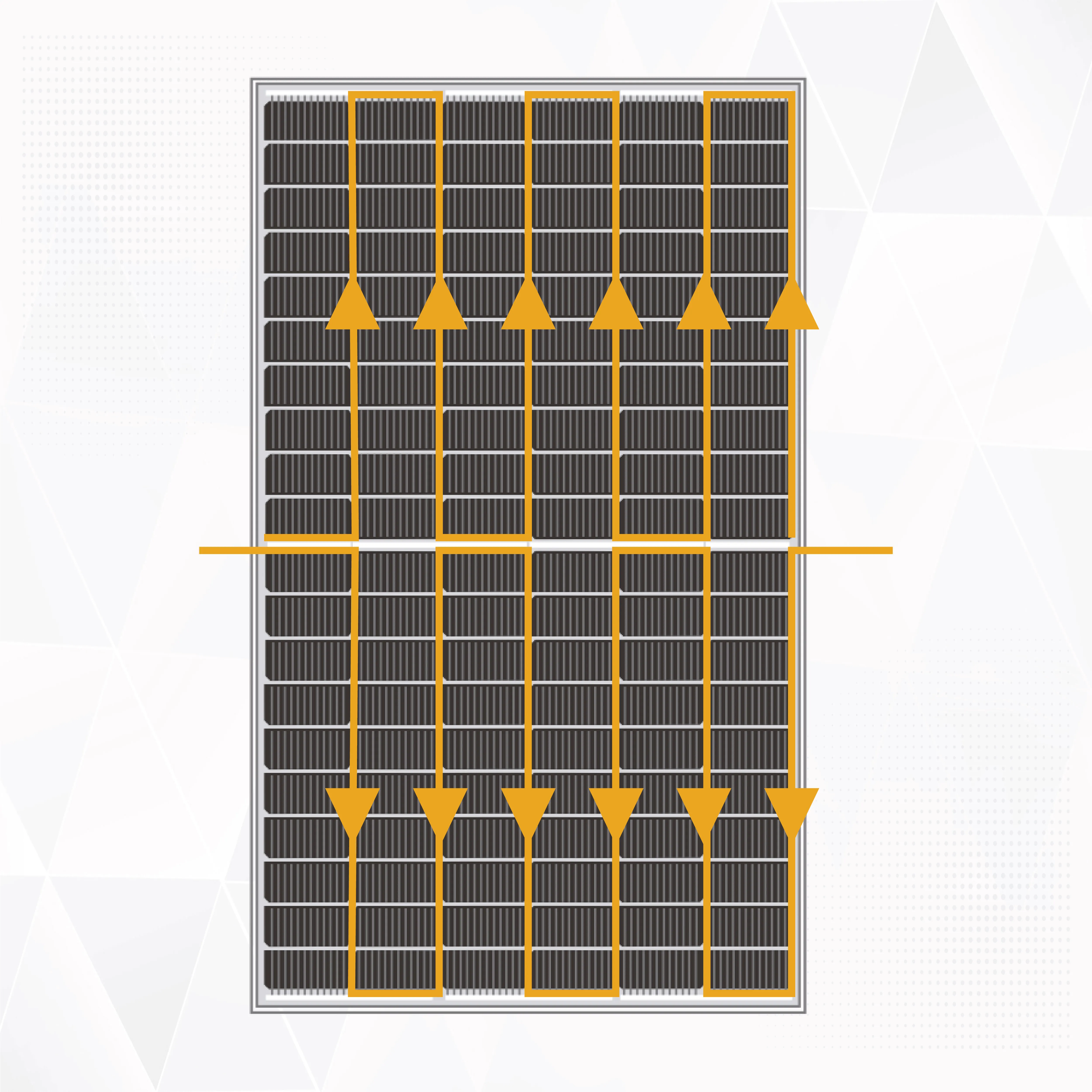

Conventional monocrystalline solar panels are generally equipped with 60 to 72 solar cells. By slicing these cells in half, the count effectively doubles, leading to panels featuring 120 to 144 half-cut cells. These enhanced panels are also integrated with PERC technology, further boosting their efficiency. The halving process, executed with precision using a laser, reduces the current flowing through each cell, thereby minimizing resistive losses associated with energy transfer. This results in a notable performance uptick. With cells halved and consequently smaller, a higher cell count is achieved on the panel compared to standard configurations. This division into two halves enables the top and bottom sections to function as independent entities, ensuring continued electricity generation even when one half experiences shading.

A critical aspect of the half-cut cell architecture is its unique approach to "series wiring," or the manner in which solar cells are interconnected and how power is directed through a bypass diode within the panel. In traditional panels, shading or malfunctioning of a single cell can halt power production across the entire row of cells connected in series.

Half-Cut Solar Panel Vs Full Cell:

Traditional panels typically outfitted with either 60 or 72 cells, are redesigned in half-cell modules to include double the number – 120 or 144 cells – while maintaining the original panel size. This doubling in cell count doesn't change the panel's physical dimensions but significantly enhances its capacity to harness and convey solar energy to the inverter.

The essence of half-cell technology lies in bisecting cells to diminish resistance and elevate efficiency. Whereas conventional panels with 60 or 72 cells encounter resistance that curtails their power generation capacity, half-cell panels, boasting 120 or 144 cells, face lower resistance. This reduction means that they can capture and convert more solar energy. Additionally, the distribution of smaller cells across each half-cell panel reduces the mechanical stress on the panel, minimizing the risk of microfractures. Moreover, panels employing half-cell technology not only exhibit superior power output ratings but also tend to be more reliable than their full-cell counterparts.

What makes half-cut solar cells more efficient?

The half-cut solar cell represents an evolved form of the traditional solar cell, integrating advanced technologies to enhance the efficiency and longevity of solar panels.

To augment the performance and durability of half-cut solar cells, several innovative approaches are employed, including:

- A greater number of busbars

- A divided junction box configuration

- Cell passivation techniques

Increased Number of Busbars:

Busbars are slender metallic strips placed on the front and back of the solar panel, crucial for connecting the solar cell and facilitating the flow of DC electricity. While older solar panels typically featured two busbars, modern advancements have led to the adoption of five or nine busbars to boost energy efficiency significantly. The advantages of this increase include:

- Reduced distance for electron travel to the ribbons, enhancing current flow.

- Lowered internal resistance due to the shorter distance, thereby elevating the efficiency and durability of the cell.

Split Junction Box:

The split or dual junction box design is a notable innovation in half-cut solar cells. Traditionally encompassing a single unit, the junction box connects the solar panel to the broader system through a bypass diode. In contrast, split cell technology, through its utilization of a split junction box divided into three sections, each with its own bypass diode and internal string, optimizes voltage by minimizing solar cell size.

Cell Passivation Technology:

Another critical advancement is "passivation technology," which involves the application of a special dielectric layer on the rear side of the cell, above the aluminum metallization layer. This layer, known as PERC (Passivated Emitter Rear Cell), plays a pivotal role in capturing reflected solar radiation and generating energy even under low-light conditions. Additionally, it minimizes atom recombination, contributing to lower cell temperatures and improved efficiency.

Differences in advantages and disadvantages between half-cut and traditional solar cells:

| Feature | Half-Cut Solar Cells | Traditional Solar Cells |

|---|---|---|

| Power Production and Performance | Enhanced due to unique wiring, tolerant to shadows, offering high performance even in partial shade. | Reduced performance in shaded conditions due to standard wiring arrangements. |

| Wattage and Efficiency | Higher wattage, resulting in more electricity generation per square foot. | Typically lower wattage (around 250 watts), less efficient per square foot. |

| Hot Spots | Reduced severity of hot spots due to more cells distributing excess heat. | More susceptible to damage from hot spots due to fewer cells. |

| Internal Resistance and Power Loss | Lower internal resistance, minimizing power loss due to the halved current of each cell. | Higher internal resistance, leading to more significant power loss. |

| Cost | Higher initial costs due to additional soldering and laser cutting processes. | Lower initial costs with standard manufacturing processes. |

| Manufacturing Complexity and Defects | Increased complexity, requiring more equipment and potentially leading to more cell defects. | Simpler manufacturing process with a lower chance of defects due to fewer soldered connections. |

Is Investing in Half-Cut Solar Panels a Smart Choice?

Half-cut cells significantly enhance the power output of solar panels, yet their complex production process presents challenges for solar module manufacturers. Adapting existing production lines to accommodate half-cell solar modules is not straightforward, requiring more than just integrating half-cut cells.

Conventional solar panels remain effective in various scenarios, especially in locations where sunlight is abundant throughout the day. However, for those aiming to maximize energy generation, such as individuals in remote areas or those looking to optimize net metering advantages, half-cut cells are an ideal choice. They are particularly beneficial when space is limited but the need for solar energy is high. As manufacturing processes for half-cut cells become more efficient and easier to integrate, it's likely that their cost will decrease, making them a more prevalent option. PIXON as a solar module manufacturer can provide valuable advice on whether half-cut cells are a suitable solution for your solar energy needs.