Quality vs. Quantity: What Modern Solar Customers Actually Want

In the ever-evolving world of solar energy, there is often a debate between quality and quantity. As modern solar customers, it can be challenging to navigate through the myriad of options and determine what truly matters to us. Are we more concerned about having the highest number of solar panels possible, or do we prioritize the highest quality materials and technology? In this newsletter, we aim to explore what modern solar customers actually want and how we can make informed decisions that align with our values and goals. Let's dive in and shed some light on this important topic together.

Background

In large-scale solar installations, the traditional metric of success has often been MW installed. However, system operators and investors are increasingly recognising that module quality, material science and degradation rates have more significant long-term financial and performance implications than initial quantity or cost. PIXON's vertically integrated manufacturing of solar modules and EVA films offers unique insights into how high-spec materials and controlled production environments can deliver enhanced performance over 30 years.

Key Technical Factors Driving the Shift Towards Quality

1. Degradation Rate Matters More Than Initial Wattage

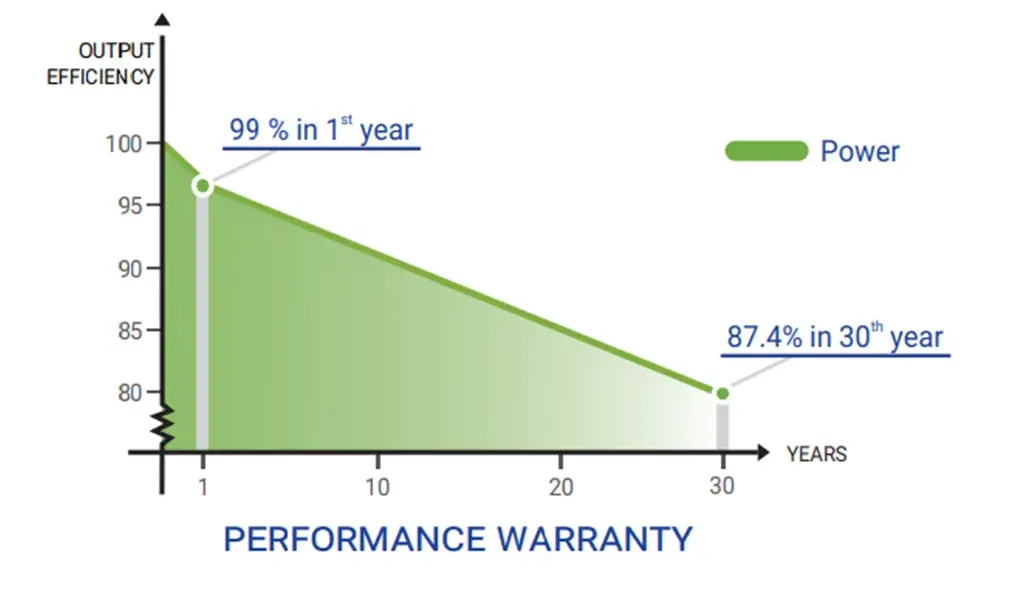

- Lower-cost, high-volume modules often degrade at >0.7% per year , while premium modules can achieve rates as low as 0.3-0.45% annually .

- Over 30 years, this difference can result in 8-12% more energy yield, directly impacting LCOE (Levelised Cost of Energy).

- PIXON's use of advanced encapsulants (e.g. POE, Ultra-Fast Cure EVA) ensures minimal potential-induced degradation (PID) and higher light transmission.

2. Module Efficiency & BOS Cost Optimisation

- High-efficiency modules (e.g. Mono PERC Half-Cut cells) reduce the number of panels needed per MW.

- This leads to:

- Fewer structures

- Lower cabling costs

- Reduced labour and installation timelines

- PIXON's modules offer efficiencies up to 21.20% , cutting BOS cost per Wp significantly.

3. Material Integrity & Long-Term Performance

- Cheaper modules often use low-grade EVA that yellows, shrinks, or delaminates under UV or damp-heat exposure.

- PIXON EVA films are engineered for:

- UV stability (≥3,000 hours tested)

- Lower shrinkage ❲ <2% ❳

- PID resistance at 85°C/85% RH

- These properties ensure optical and mechanical stability, critical in hot and humid climates.

4. Thermal Management & Energy Yield

- High-quality modules maintain lower operating temperatures due to better material conductivity and uniform lamination.

- This improves:

- Temperature Coefficient Stability

- Output under NOCT (Nominal Operating Cell Temperature)

- Result: Higher average daily yield, especially in tropical installations.

5. Glass-to-Glass vs. Backsheet Module Choices

- Glass-to-glass modules offer:

- Improved mechanical strength

- Double-sided encapsulation (ideal for bifacial applications)

- Longer durability under high wind/snow loads

- PIXON manufactures both Glass-to-Glass and Transparent Backsheet modules, tailored to site-specific requirements.

6. Encapsulant Engineering = Reliability Backbone

- Many module failures originate in EVA degradation. PIXON’s cleanroom-manufactured encapsulants ensure:

- Controlled cross-linking

- Even lamination without voids

- Fast-curing properties that reduce thermal stress during lamination

- Use of POE film further improves resistance to moisture ingress and PID, particularly important in coastal and high-humidity zones.

7. Certifications, Testing & Traceability

- Premium modules come with:

- IEC 61215, IEC 61730, IEC 62804 (PID), and Salt Mist/Ammonia Corrosion certifications

- EL testing before and after lamination

- Serialised data matrix codes for traceability

- PIXON integrates advanced QC protocols at both EVA and module levels to ensure long-term product reliability.

Here is a comparative chart showing the retained energy output over 30 years for PIXON premium modules (0.45% annual degradation) versus standard modules (0.70%). As illustrated, PIXON modules retain significantly more energy—resulting in up to 12% higher lifetime energy yield .

Key Takeaway

Modern solar customers—especially utility-scale project owners—require bankable, reliable, and low-maintenance assets. The upfront cost advantage of quantity-focused procurement is quickly outweighed by the risks of performance loss, higher O&M costs, and financial underperformance over 30 years.

Technical advantage lies in:

- High-efficiency, low-degradation modules

- Advanced encapsulants with PID and UV resistance

- Reduced BOS cost through higher output per panel

- Proven durability with certifications and real-world performance

PIXON’s Role in the Quality Paradigm

- With in-house production of both solar modules and EVA/POE films, PIXON delivers full-stack control over material quality and lamination processes—something that few manufacturers globally can claim.

- This integration not only enhances consistency and traceability but ensures each module is engineered for real-world resilience , not just factory output.

Key Technical Resources & References

1. IEC Standards for Solar Modules:

- IEC 61215: Design qualification and type approval

- IEC 61730: Safety qualification

- IEC 62804: PID resistance testing

- IEC 62716: Ammonia corrosion test

- IEC 61701: Salt mist corrosion testing

2. NREL (National Renewable Energy Laboratory) Reports:

- “Photovoltaic Degradation Rates — An Analytical Review”

- “Best Practices for PV Module Reliability”

3. PI Berlin & TÜV Reports (relevant to encapsulant performance & PID resistance):

- Encapsulant ageing and UV degradation studies

- Cross-linking density and shrinkage analysis of EVA vs. POE

4. PIXON Internal Quality Control Data:

- Controlled lamination using Clean Room for EVA/POE film

- Serialised traceability system for each module batch

- In-house accelerated ageing tests (UV, DH, TC, PID)

5. Software Tools (for further analysis):

- PVsyst (energy simulation incorporating degradation rates)

- SAM (System Advisor Model by NREL)

- PAN files of PIXON modules for project-specific simulations