The solar energy industry has witnessed remarkable advancements over the past decade, driven by innovations in new solar panel technologies. At the core of this evolution lies solar wafers, a crucial element in manufacturing solar pv modules. Understanding solar wafers, their types, and applications helps us appreciate the role they play in achieving efficient and sustainable solar energy solutions.

In this blog, we will explore the fundamentals of solar wafers, their applications in solar technology, and the different types available in the market. Whether you are an investor, manufacturer, or solar energy enthusiast, this guide will provide valuable insights into this essential photovoltaic component.

What Are Solar Wafers?

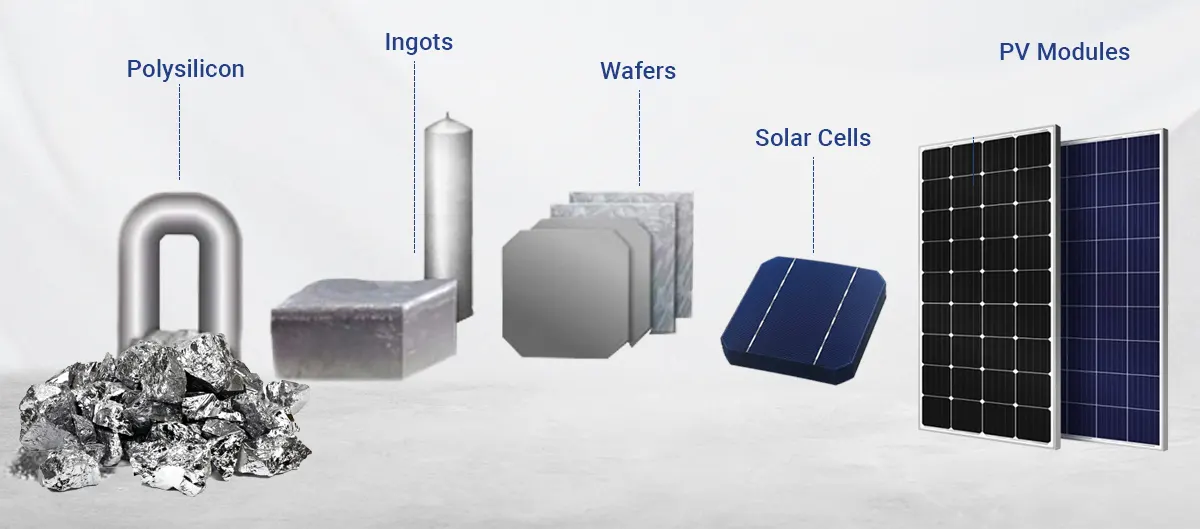

A solar wafer, also known as a silicon wafer, is a thin slice of crystalline silicon that serves as the foundation for fabricating integrated circuits in photovoltaics (PVs). It plays a crucial role in manufacturing solar cells by acting as a semiconductor substrate for microelectronic devices. The production of high-quality solar wafers is vital for ensuring the efficiency and longevity of solar pv modules.

The production of wafers involves highly pure (99.9999999% purity), nearly defect-free single crystalline material. The solar industry primarily utilizes polysilicon and silicon wafers. Additionally, monocrystalline and multicrystalline wafers are employed to meet specific customer requirements.

How Does it Function?

These solar cells draw inspiration from nature. Similar to how plants use photosynthesis, wafer solar cells capture and store energy during the day, making it available for use at night.

Sunlight Absorption: Just as plants soak up sunlight, the solar cell's surface captures sunlight, initiating the energy conversion process.

Photon Penetration: Photons, the tiny energy carriers in light, travel through the cell's layers, resembling sunlight filtering through leaves.

Energy Conversion: As photons reach the lower layer, they transfer energy to electrons, setting them in motion.

Electron Flow: Energized electrons break free from their atoms and enter the circuit, generating electrical current.

Powering Devices: These electrons circulate through the circuit, supplying energy to power everything from smartphones to entire homes.

Applications of Solar Wafers

1. Solar Panel Manufacturing

Solar wafers are the primary building blocks of solar panels manufacturing companies. They are processed into solar cells, assembled into solar pv modules, and used by top solar panel manufacturers in India to produce efficient solar panels for residential, commercial, and industrial applications.

2. Consumer and Industrial Electronics

Apart from solar power generation, solar wafers are used in various electronic devices, including calculators, smartwatches, and spacecraft applications where renewable energy sources are necessary.

Types of Solar Wafers

The choice of wafers depends on specific business needs and applications.

Single-crystal solar wafers are the most commonly used type, available in three main categories:

Type A: The most widely used solar wafer, boasting a purity level of 99.999%. It is essential in smartphones, video recorders, and computer storage devices, as well as in applications requiring high density and performance.

Type B: With an even higher purity than Type A, Type B wafers are more challenging to manufacture. They are primarily used in biosensors and high-quality color hardware applications.

Type C: A cost-effective alternative to Type B, Type C wafers have a slightly lower purity level but remain suitable for most applications. They are widely used in logic chip production, enabling integrated circuits to power computers and smartphones, facilitating data transmission and operational functions

Silicon wafers are broadly categorized into two types

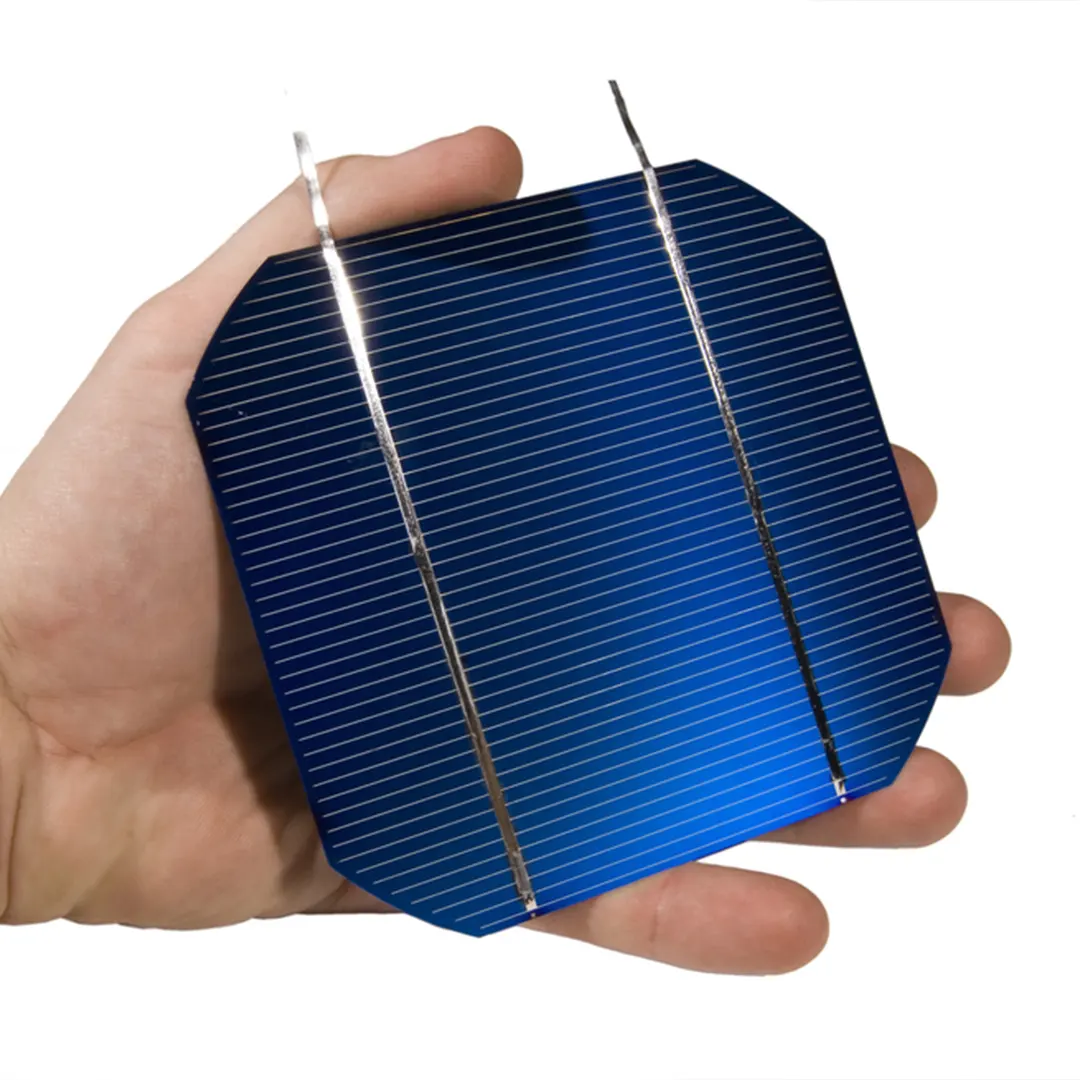

Monocrystalline Silicon Wafers

These wafers are composed of a single continuous crystal structure, ensuring superior efficiency and enhanced performance, especially in low-light conditions.

Polycrystalline Silicon Wafers

Formed from multiple silicon crystals, these wafers are a more cost-effective option but generally offer lower efficiency compared to their monocrystalline counterparts.

Advantages of High-Quality Solar Wafers

Increased Efficiency: Higher purity and precision in wafer manufacturing result in more efficient solar energy conversion.

Longer Lifespan: Premium wafers ensure a longer operational life for solar pv modules.

Enhanced Performance: Cutting-edge new solar panel technologies improve wafer performance, leading to better power output.

Cost-Effectiveness: While high-quality wafers may be expensive, they offer better returns in the long run.

Choosing the Right Solar Wafers for Your Needs

When selecting solar wafers, it is essential to consider factors such as efficiency, cost, durability, and application requirements. Leading solar panels manufacturing companies invest heavily in R&D to develop wafers that optimize energy output while minimizing costs.

To explore high-quality solar wafers and solar pv modules, visit our product page .

Wrapping Up:

Solar wafers play a pivotal role in determining the efficiency and longevity of solar pv modules. Whether it's mono perc solar panels , polycrystalline modules, or thin-film technologies, understanding the different types and their applications can help in making informed decisions.

As one of the leading solar panel manufacturers, we offer high-quality, durable, and efficient photovoltaic panels. Explore our range of solar products by visiting our homepage or contact us for inquiries.

FAQ Section

Monocrystalline wafers are considered the best due to their high efficiency and durability, making them ideal for premium solar energy manufacturer applications.

High-quality solar wafers, when used in solar panels manufacturing companies, can last over 25-27 years with proper maintenance.

Thin-film wafers are flexible and cost-effective, but crystalline wafers provide higher efficiency and better performance.

With continuous advancements in latest technology in solar panels, future wafers will be even more efficient, cost-effective, and environmentally friendly.