Revolutionizing Solar Encapsulation- The Rise of EPE for Bifacial Modules and Advanced Cell Architectures

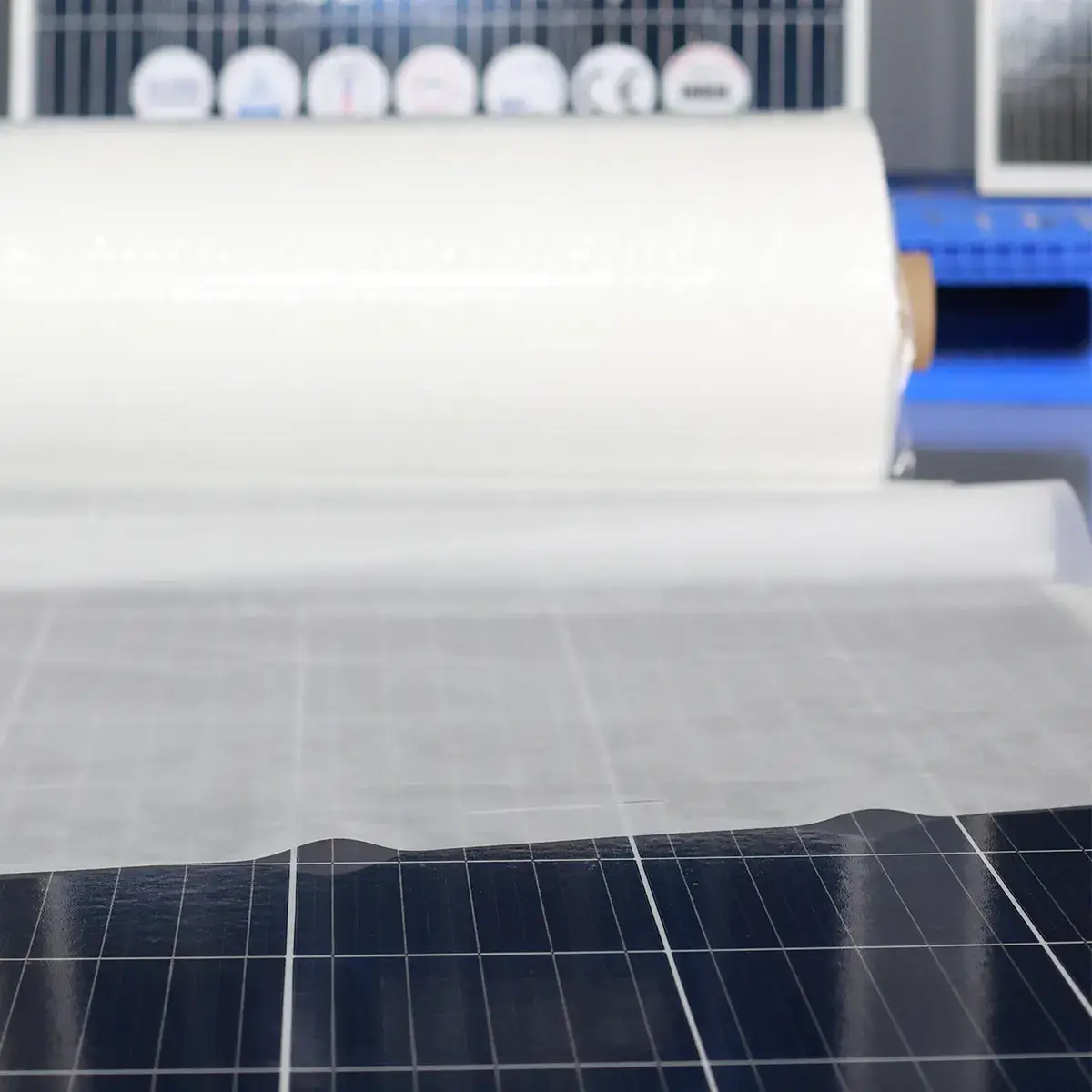

As the world races toward a sustainable future, the importance of solar energy cannot be overstated. Solar photovoltaic (PV) modules are at the heart of this revolution, converting sunlight into clean, renewable electricity. However, the choice of encapsulation material is critical for the performance, durability, and longevity of these modules. In recent years, encapsulation material suppliers have been working diligently to address the shortcomings of traditional materials like Ethylene-Vinyl Acetate (EVA) and Polyolefin Elastomer (POE). The result of their efforts is a groundbreaking innovation - the co-extruded multilayer structure EVA-POE-EVA, also known as EPE, designed specifically for bifacial modules.

The Shortcomings of EVA and POE

EVA (Ethylene-Vinyl Acetate)

EVA has long been a popular choice as an encapsulation material for solar PV modules. It boasts excellent adhesive properties and exceptional optical transmission, allowing maximum sunlight to reach the solar cells. However, EVA does have its limitations, the most significant of which is its low resistance to Potential-Induced Degradation (PID). PID is a phenomenon where the electrical performance of PV modules degrades due to voltage stress, and EVA, unfortunately, falls short in addressing this issue.

POE (Polyolefin Elastomer)

Recognizing the limitations of EVA, many module manufacturers turned to POE as an alternative encapsulant. POE is known for its high resistance to water vapor and PID. Additionally, it doesn't suffer from issues like acid and free radical formation. These qualities made it an attractive choice, especially for the rear side of Passivated Emitter Rear Contact (PERC) bifacial modules.

Nonetheless, POE presents a distinct set of challenges. During the lamination process, when using POE film, it's easy to generate bubbles, compromising the module's integrity. Moreover, the lamination time for POE is longer, requiring approximately 6 minutes more per lamination cycle. Furthermore, the adhesion properties of POE to glass are inferior to that of EVA.

The Evolution of EPE - Combining the Best of Both Worlds

In response to the limitations of EVA and POE, encapsulation material suppliers have engineered a groundbreaking solution - the co-extruded multilayer structure EVA-POE-EVA, or simply EPE. This innovative design aims to leverage the most advantageous qualities of both EVA and POE encapsulants.

The EPE Structure

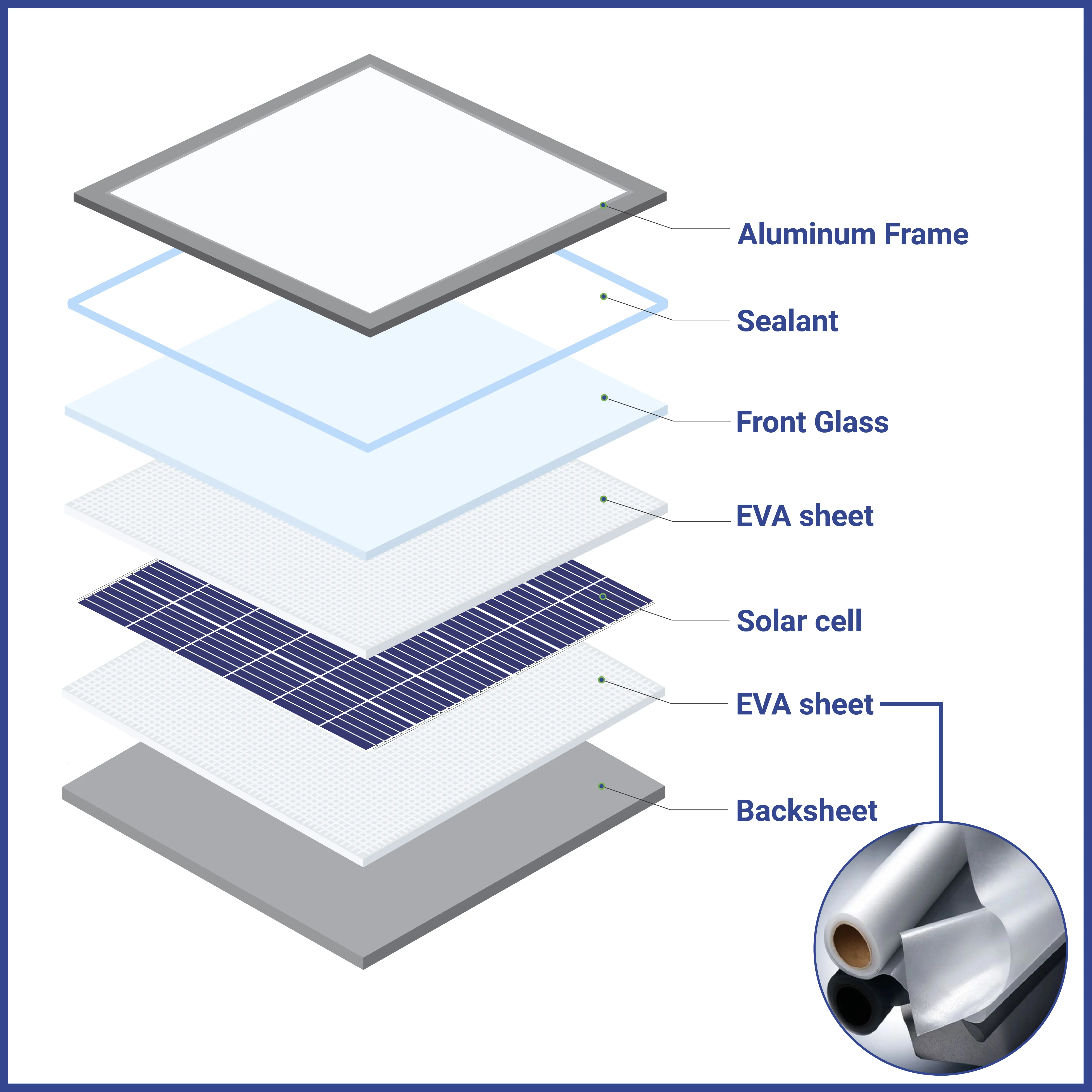

EPE encapsulant consists of a thin layer of POE sandwiched between two layers of EVA. This structure is manufactured via coextrusion, ensuring precise control over the encapsulation process. Each layer serves a specific purpose:

Outer EVA Layers: These layers provide enhanced adhesion to both the solar cells and the glass cover of the PV module.

Central POE Layer: The POE layer acts as a superior water vapor barrier, significantly improving anti-PID performance. This layer serves as a critical defense against moisture ingression, a common challenge faced by traditional encapsulants.

To prevent acid formation, specially developed acid-free EVA is used in EPE configurations. The result is a highly effective encapsulation material that combines the adhesive properties of EVA, the water vapor resistance of POE, and superior anti-PID performance.

Lamination Time

One significant advantage of EPE is its lamination time, which strikes a balance between that of EVA and single-layer POE. While EVA requires approximately 600 seconds for lamination, single-layer POE needs only about 300 seconds. EPE, on the other hand, optimizes the process with a lamination time of approximately 450 seconds. This not only enhances the efficiency of the manufacturing process but also addresses one of the drawbacks of traditional POE.

Expanding Applications of EPE in Modern Cell Architectures

One significant advantage of EPE is its lamination time, which strikes a balance between that of EVA and single-layer POE. While EVA requires approximately 600 seconds for lamination, single-layer POE needs only about 300 seconds. EPE, on the other hand, optimizes the process with a lamination time of approximately 450 seconds. This not only enhances the efficiency of the manufacturing process but also addresses one of the drawbacks of traditional POE.

TOPCon Cells

TOPCon cells, known for their high efficiency, do have specific requirements when it comes to encapsulation. These cells are more sensitive to moisture ingress compared to PERC cells. Therefore, EPE is an excellent choice for encapsulating TOPCon bifacial modules. Its superior water vapor barrier properties make it an ideal match for these advanced cell architectures.

HJT Cells

HJT cells, which utilize Tunnel Oxide Passivated Contact technology on both sides, present unique challenges in terms of adhesion. While they exhibit low adhesivity with POE, they have good adhesion with EVA. However, EVA alone may not provide the required moisture barrier for the long term. This is where EPE comes into play.

Glass-Glass Modules

EPE encapsulant is particularly well-suited for Glass-Glass solar panels that utilize PERC, TOPCon, or HJT cells. These modules benefit from EPE's enhanced anti-PID properties and superior water vapor barrier.

For Glass-Glass modules, it's often recommended to use POE on both sides to maximize performance. However, this approach may not be ideal for passing the damp heat test due to poor adhesion to glass, Additionally, due to the current shortage of EVA raw materials, some companies are seriously considering the possibility of employing EPE encapsulant on the front side as well.

Cost Considerations

The cost of EPE encapsulant depends on the raw material prices of EVA and POE. Generally, the raw material price of POE is higher than that of EVA. However, the prices of EVA resin are currently very high and volatile due to supply shortages. Manufacturing EPE is slightly costlier than producing a single film because of the complexity of the coextrusion process. The waste generated during edge trims cannot be recycled, adding to production costs. In the end, the price difference mainly hinges on the resin prices of EVA and POE.

Conclusion

The development of the co-extruded multilayer structure EVA-POE-EVA (EPE) encapsulant represents a significant advancement in the field of solar PV module technology. By combining the strengths of both EVA and POE, encapsulation material suppliers have addressed critical limitations, providing an effective solution for bifacial modules and modern cell architectures like TOPCon and HJT. EPE's ability to offer superior water vapor resistance, anti-PID performance, and adhesion properties makes it a promising choice for the future of solar energy generation. As the solar industry continues to evolve, EPE encapsulant is likely to play an increasingly central role in enhancing the efficiency and durability of solar PV modules, ultimately contributing to a more sustainable and cleaner energy future.