What is Solar Cell?

A solar cell, also known as a photovoltaic cell, is an electronic device that converts light energy directly into electrical energy by the photovoltaic effect.

Solar cells are commonly used in solar panels, which are arrays of solar cells that work together to produce more power. They are used to generate electricity in a variety of applications, including residential and commercial buildings, remote power systems, and spacecraft.

What is Solar Cell Technology?

Solar cell technology, also known as photovoltaic technology, is a rapidly advancing field of research and development aimed at harnessing the power of the sun to generate electricity. This technology has the potential to revolutionize the way we produce and consume energy, as it is a clean and renewable source of power that can be harnessed in virtually any location.

Solar cells convert sunlight into electricity through a process called the photovoltaic effect, which involves the interaction of photons with semiconductor materials such as silicon. The increasing efficiency and decreasing costs of solar cells have made them a viable alternative to traditional fossil fuels, and they are now being deployed on a large scale in many parts of the world.

In this context, it is important to understand the basic principles behind solar cell technology, its various applications, and its potential to transform our energy landscape. Each type of solar cell technology has its own unique set of advantages and disadvantages, and the choice of which one to use will depend on various factors such as cost, efficiency, and application.

There are several types of solar cell technologies, each with its own unique features, advantages, and disadvantages. Here are some of the most common types:

What is PERC solar cell technology?

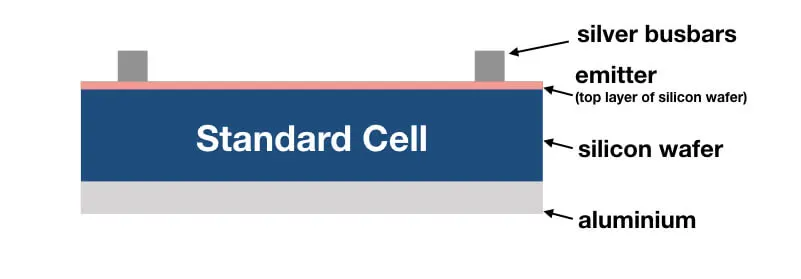

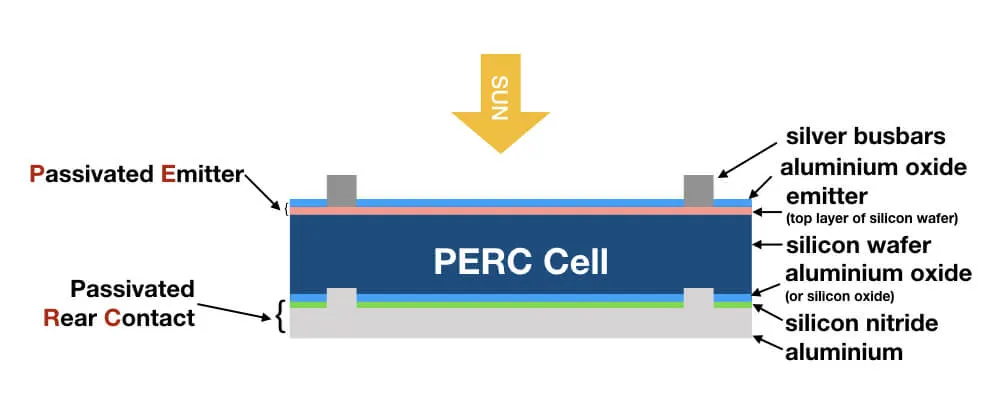

There are many kinds of solar panel technologies for customers to choose from. “Passivated Emitter and Rear Contact” solar cells, known as PERC solar cells, are becoming more common today as an option for making solar panels. PERC solar cells are modified conventional cells that enable the cells to produce 6 to 12 percent more energy than conventional solar panels. PERC solar cells have an extra layer within the back side of the cell. This allows some of the sun’s rays to reflect back into the solar cell, giving them another opportunity to be turned into energy.

Since PERC solar cells are a modification of conventional cells, they can be manufactured using the same equipment. This makes it easy for manufacturers to change and produce the higher efficient cells. With the higher efficient cells, it will take fewer panels to produce the same amount of electricity when compared to a conventional panel.

However, this modification creates a vulnerability within the technology. Most PERC solar panels have metal strips or ribbons running through them. If these strips crack or disconnect, they are more likely to lose the ability to generate electricity. PERC panels, in Performance can generate 35% more energy over 25 years in the same space compared to other PERC panels.*

Reducing electron recombination

– electron recombination blocks the free flow of electrons through the cell, reducing efficiency. The extra passivation layer makes the flow of electrons more steady and consistent thereby producing additional electric current.

Reflecting specific wavelengths that normally generate heat out of the solar cells

– certain wavelengths are absorbed by the rear layer of the solar cell accumulating heat and reducing efficiency. The additional passivation layer reflects these wavelengths out of the solar cell maintaining the temperature of the solar cell.

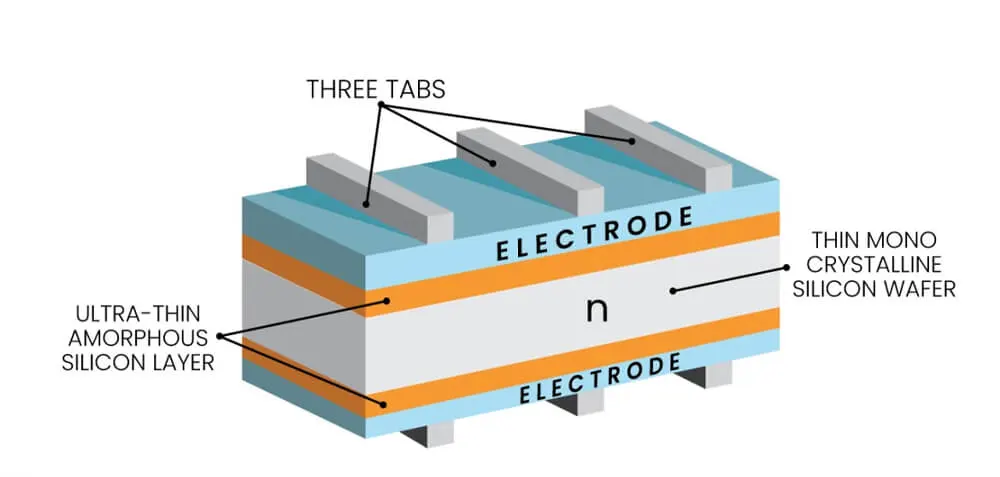

What Is Heterojunction Solar?

Heterojunction technology (HJT) is a solar panel production method that has been on the rise since last decade. It is currently the solar industry’s most effective process for increasing efficiency and power output to the highest levels. It even surpasses the performance of PERC, the solar industry’s current go-to technology.

Today, HJT modules can reach efficiencies of up to 25%.

How does HJT work?

Heterojunction solar panels are composed of three layers of photovoltaic material. HJT cells combine two different technologies into one: crystalline silicon and amorphous “thin-film” silicon.

The top layer of amorphous silicon catches sunlight before it hits the crystalline layer, as well as light that reflects off the below layers. However, monocrystalline silicon, the middle layer, is responsible for turning most of the sunlight into electricity. Lastly, behind the crystalline silicon is another amorphous thin-film silicon layer. This final layer captures the remaining photons that surpass the first two layers.

Using these technologies together allows more energy to be harvested as opposed to using them individually, reaching efficiencies of 25% or higher.

Advantages of Heterojunction Solar Cells

Here are a few key advantages of using HJT solar cells for your building:

Higher efficiency

– Most HJT panels that are currently on the market have efficiencies ranging from 19.9%–21.7%. This is a massive improvement compared to other conventional monocrystalline cells.

Cost savings

– The amorphous silicon used in HJT panels is a cost-effective photovoltaic technology. This thin-film solar requires shorter manufacturing compared to other technologies. Because of its simplified manufacturing process, HJT has the potential to be more affordable than alternative solutions.

Resilience and adaptability

– This technology was developed for excellent production capabilities, even in extreme weather conditions. HJT panels have lower temperature coefficient than conventional solar panels, ensuring high performance at elevated external temperatures.

Life expectancy

– On average, thin-film photovoltaic modules have a life expectancy of up to 25 years, while HJT solar cells can remain fully functioning well over 30 years.

The Future of HJT Solar

Given the several advantages of HJT solutions, it is likely that more companies will continue to adopt this technology in the near future. Because the HJT manufacturing process requires four fewer steps than PERC technology, there is potential for significant cost savings. While PERC has been a popular option in the industry for many years, its complex manufacturing process cannot compete with HJT. In addition, PERC does not offer HJT’s high temperature performance benefit.

According to the ITRPV 2019 report, HJT cells are expected to gain a market share of 12% by 2026 and 15% in 2029.

What is a TOPCON solar cell?

TOPCON (also known as passivated contact) solar cell, is touted as the next generation of solar cell technology after PERC. This novel architecture is introduced by researchers at Fraunhofer Institute for Solar Energy Systems in Germany in 2013.

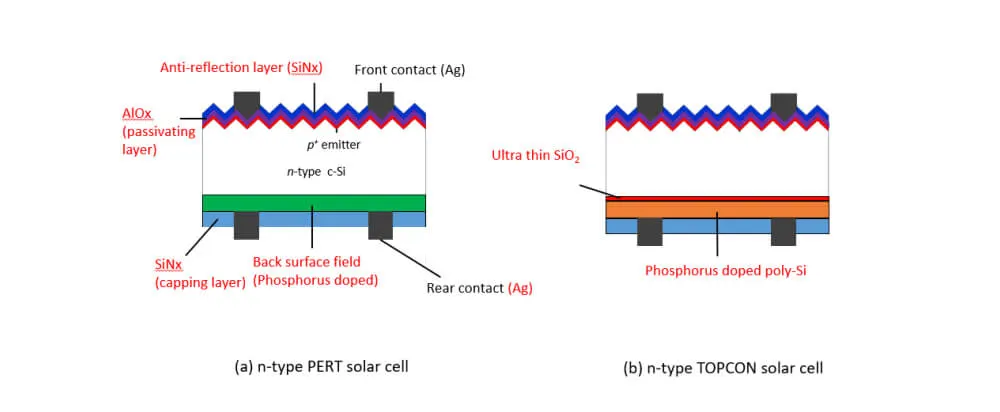

Compared to the other potential new technologies, such as HJT and IBC, TOPCON can be upgraded from the current PERC or PERT line. As a result, lower capital investment is needed for existing PERC or PERT manufacturers who are looking to upgrade their existing production lines. Moreover, a good gain in solar cell efficiency can also be achieved. This is ~1% in absolute value as reported in TOPCON is the acronym for “Tunnel Oxide Passivated Contact”. Figure 1 show this cell architecture as compared to a n-PERT solar cell.

Figure 1. n-PERT compared to n-TOPCON solar cell architectures

As shown in the figure, n-PERT and n-TOPCON are quite similar. Typically, to upgrade an n-PERT solar cell to a n-TOPCON solar cell, only an additional ultra thin SiO2 layer and a doped poly-Si layer are required. The ultrathin SiO2 acts as surface passivation layer between the rear Si surface and the rear “contact” – the poly-Si layer. In addition, it also needs to be thin enough so that current can tunnel through it quantum mechanically.

The poly-Si layer is highly doped to produce a high conductivity layer. This high conductivity layer will then acts as a contact for current collection. Additionally, in a n-type TOPCON, the poly-Si layer is typically doped with phosphorus to provide field passivation (back surface field). This is similar to the phosphorus doped rear surface of n-PERT as shown in figure 1(a).

With the addition of the tunnel oxide layer, the original authors at Fraunhofer Institute for Solar Energy Systems reported an increase of ~1% in absolute solar cell efficiency [1] [2].

There are many different types of solar cell technologies on the market today. Three of the most popular are PERC, Hetrojunction HJT and TopCon. Each has its own unique benefits. Here is a look at each one:

- PERC cells are made with a Passivated Emitter Rear Cell design. This means that the rear surface of the cell is covered with a thin layer of silicon nitride which improves light absorption and reduces reflection losses. This results in higher efficiency levels than traditional cells.

- Hetrojunction HJT cells are made with two different types of silicon, creating a heterojunction between them. This increases energy production by preventing charge recombination – meaning more electricity is produced from each photon absorbed.

- TopCon cells use transparent conductive oxides (TCOs) to create a top contact layer on the cell surface. This allows more sunlight to be absorbed, increasing efficiency levels over traditional cells.

Aiming at the mainstream technical routes of PERC, TOPCon and Heterojunction HJT, comparisons are made from the perspectives of efficiency, cost, and craftsmanship:

1) From the perspective of efficiency:

The theoretical limit efficiency of TOPCon Cell reaches 28.7%, which is higher than 27.5% of Heterojunction HT and 24.5% of PERC. Judging from the current mass production efficiency, PERC has reached around 23%, TOPCon and HT have exceeded 24%, but there is still a certain gap from the limit efficiency, and there is more room for efficiency improvement.

2) From a process point of view:

PERC is currently the most mature, TOPCon needs to add diffusion, etching and deposition equipment to the PERC production line, and the cost increase is small; while the HJT Solar Cell process is the simplest and the least steps (the core process is only 4 steps), But basically completely replaced the PERC production line. The IBC Solar Cell process is the most difficult and complex. The need is to use ion implantation to provide the production technology threshold.

3) From a cost point of view:

PERC industrialization is the fastest and low cost, and TOPCon Solar Cell has the highest compatibility. It can be upgraded from PERC/PERT production line, followed by IBC. HJT Solar Cell is completely incompatible with existing equipment, and a new production line is required. GW investment is 250 million yuan higher than PERC and nearly 200 million yuan higher than TOPCon. There is still room for decline.

TOPCon: Extend the life cycle of PERC production line, the first choice for cost performance in the next 2-3 years.In the past two years, PERC's newly-built production lines have reserved space for TOPCon transformation, and the current expansion plans have also shifted to the construction of N-type technology production lines. Facing the huge PERC cell production capacity at present, TOPCon and PERC cell technology and production line equipment are highly compatible.

The existing equipment of the PERC production line is mainly modified, and the main new equipment is the LPCVD/PECVD equipment and coating of amorphous silicon deposition. Equipment link.

Heterojunction HJT: There is a lot of room for localization to reduce costs, and it is expected to become the next-generation mainstream technology.

1) Double-sided power generation improves efficiency. Heterojunction HT double-sided symmetrical structure, the power generation exceeds the single-sided Solar Cell by 10%+, and the current double-sided rate has reached 95%, which has obvious advantages in power generation gains compared with other process routes

2) Low licht attenuation + low temperature coefficient, strong stability. The Heterojunction HJT Solar Cell reduces the interface recombination and improves the TCO layer and Ag contact performance through a good coating process. The degradation of HT Solar Cells is less than 3% in 10 years, and only 8% in 25 years. And the Solar Cell temperature coefficient is small, which can reduce the heat loss caused by sunlight/

3) The process flow is more simplified, and there is more room for efficiency improvement and cost reduction. Compared with PERC's 8 processes and TOPCon's 10 processes, Heterojunction HT can be completed in only 4 processes. It can be prepared under a low temperature environment of <250°C. Compared with traditional PN junctions prepared at a high temperature of 900°C, it is conducive to slicing and Reduce thermal damage to reduce the cost of silicon wafers, which has more advantages and room for improvement in terms of production efficiency and product vield.

4) The current production cost of Heterojunction HT Solar Cells is below 0.9 yuan/W, which is higher than the cost of PERC at 0.7 yuan/W, it is expected that in 2022, the cost of silicon and non-silicon of Heterojunction HJT Solar Cells will be reduced by 40%+ compared with the current price, which is compared with the cost-effectiveness of monocrystalline PERC Solar Cells. The advantages are expected to gradually emerge.

At present, the industry mainly starts from three aspects: silver paste, silicon wafer and equipment:

1. Silver paste cost

localization of low-temperature silver paste + silver-clad copper technology + SMBB technology, judged to jointly promote a cost reduction of more than 60%.

2. Silicon wafer cost

HJT wafers are expected to be thinner, lower costs, and improve efficiency, and the cost is expected to drop by more than 40%. Thinning is conducive to reducing the cost of silicon wafers. Heterojunction HJT cells have a symmetrical structure, which is easy to thin and does not affect efficiency. The current PERC thickness is 170um, and we expect it to drop below 130 m by 2022, which will increase Voc and further improve efficiency and reduce costs. We expect that the cost of silicon wafers will drop from 0.48 yuan/W in 2020 to 0.27 yuan/W in 2022, a reduction of over 40%:

3. Cost reduction in equipment

The current cost per GW is less than 400 million yuan, and there is still room for 40% cost reduction in the future. The Heterojunction HJT production process has ben greatly simplified. The four steps of texturing cleaning, amorphous silicon film deposition, TCO film deposition, and electrode metallization correspond to the four process equipment of texturing cleaning, PECVD, PVD/RPD, and silk screen/electroplating respectively.

In conclusion, solar cell technology has made significant strides in recent years, and it continues to be one of the most promising sources of renewable energy. Solar cells are becoming more efficient, cost-effective, and widely available, making them an attractive option for homeowners, businesses, and utilities. With continued investment and research, it is likely that solar cells will become even more efficient and accessible, helping to reduce our dependence on fossil fuels and mitigate the effects of climate change. As a clean, sustainable source of energy, solar cells offer a bright future for our planet and our society.